Abstract

The probability of failure estimation of composite structures under applied loads is an inevitable requirement given the uncertainties related to the material properties, loads, and boundary conditions. The properties of composite materials have more scatter due to non-homogeneity and anisotropic characteristics, and manufacturing defects. In this paper, the reliability of S2-Glass/Epoxy laminate composite materials containing a central circular hole under static tensile load is presented. Failure in fiber-reinforced plastic structures, since individual faults in each ply cannot be traced, is a random process due to the scatter caused by the behavior of the material. According to the continuum damage mechanics (CDM) approach, a damage model proposed by Ladeveze is used to model the matrix cracking and fiber/matrix debonding and then, the material constitutive relationships are implemented in the ABAQUS software by the subroutine. The first-order reliability method (FORM) and second-order reliability method (SORM) have been used to analyze the system failure probability of the composite plates, and the failure functions and random variables have been obtained according to the CDM approach. Scatter in random parameters have been displayed to have a significant effect on damage development. Finally, using sensitivity analysis, sensitive and effective parameters in the reliability of laminate composite were introduced.

Similar content being viewed by others

Abbreviations

- a :

-

Material parameter

- A :

-

Material coefficient

- B :

-

Material parameter

- D :

-

Scalar damage variable

- D c :

-

Critical damage

- E :

-

Young modulus of elasticity

- f :

-

Yield function of plastic criterion

- F :

-

Dissipative potential function

- F P :

-

Plastic potential function

- g :

-

Performance function

- G :

-

Shear modulus

- k :

-

Curve of performance function

- p :

-

Accumulated plastic strain

- P :

-

Probability of failure

- R :

-

Isotropic hardening

- R :

-

Reliability

- X :

-

Random variable

- Y :

-

Energy density release rate

- \(\hat{Y}\) :

-

Additional quantitative variable

- Y 12(0) :

-

Initial shear damage threshold

- Y 12( C ) :

-

Critical shear damage limit

- Y 2(0) :

-

Initial transverse damage threshold

- Y 2( C ) :

-

Critical transverse damage limit

- Y S :

-

Brittle-damage threshold

- Z :

-

Resistance

- \(\alpha\) :

-

Damage exponent

- \(\beta\) :

-

Isotropic hardening parameter

- \({\upbeta }\) :

-

Reliability index

- γ :

-

Shear strain

- \(\Gamma\) :

-

Gibbs free energy

- \(\varepsilon\) :

-

Total strains

- \(\varepsilon_{e}\) :

-

Elastic strains

- \(\varepsilon_{p}\) :

-

Plastic strains

- \(\varepsilon_{pD}\) :

-

Damage threshold plastic strain

- \(\varepsilon_{pR}\) :

-

Rupture plastic strain

- Φ:

-

Cumulative distribution function

- \(\dot{\lambda }\) :

-

Plastic multiplier

- \(\nu\) :

-

Poisson ratio

- \(\rho\) :

-

Mass density

- ξ :

-

Isotropic hardening exponent

- σ :

-

Stresses

- σ y :

-

Yield stress

References

Allix O, Ladevèze P (1992) Interlaminar interface modelling for the prediction of delamination. Compos Struct 22:235–242. https://doi.org/10.1016/0263-8223(92)90060-P

Allix O, Ladeveze P, Vittecoq E (1994) Modelling and identification of the mechanical behaviour of composite laminates in compression. Compos Sci Technol 51:35–42

Duodu E, Gu J, Ding W, Shang Z, Tang S (2018) Comparison of ballistic impact behavior of carbon fiber/epoxy composite and steel metal structures. Iranian J Sci Technol Trans Mech Eng 42:13–22

Duodu EA, Gu J, Ding W, Shang Z, Tang S (2019) Simulation of composite laminate with cohesive interface elements under low-velocity impact loading. Iranian J Sci Technol Trans Mech Eng 43:127–138

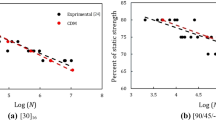

Fakoor M, Ghoreishi SMN (2018) Experimental and numerical investigation of progressive damage in composite laminates based on continuum damage mechanics. Polym Test 70:533–543

Gholami P, Kouchakzadeh MA, Farsi MA (2021a) A Continuum damage mechanics-based piecewise fatigue damage model for fatigue life prediction of fiber-reinforced laminated composites. Int J Eng 34:1512–1522

Gholami P, Farsi MA, Kouchakzadeh MA (2021b) Stochastic fatigue life prediction of fiber-reinforced laminated composites by continuum damage mechanics-based damage plastic model. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2021.106456

Gosling PD, Polit O (2014) A high-fidelity first-order reliability analysis for shear deformable laminated composite plates. Compos Struct 115:12–28

Ladeveze P (1992) A damage computational method for composite structures. Comput Struct 44:79–87. https://doi.org/10.1016/0045-7949(92)90226-P

Ladeveze P, LeDantec E (1992) Damage modelling of the elementary ply for laminated composites. Compos Sci Technol 43:257–267. https://doi.org/10.1016/0266-3538(92)90097-M

Lemaire M (2013) Structural reliability. John Wiley & Sons

Lemaitre J, Desmorat R (2005) Engineering damage mechanics: ductile, creep, fatigue and brittle failures. Springer, Berlin

Maa R-H, Cheng J-H (2002) A CDM-based failure model for predicting strength of notched composite laminates. Compos B Eng 33:479–489

Maimí P, Camanho PP, Mayugo J, Dávila C (2007) A continuum damage model for composite laminates: part I-constitutive model. Mech Mater 39:897–908

Maire J, Chaboche J (1997) A new formulation of continuum damage mechanics (CDM) for composite materials. Aerosp Sci Technol 1:247–257

McCarthy CT, McCarthy MA, Lawlor V (2005) Progressive damage analysis of multi-bolt composite joints with variable bolt–hole clearances. Compos B Eng 36:290–305

Mukhopadhyay S, Hallett SR (2019) A directed continuum damage mechanics method for modelling composite matrix cracks. Compos Sci Technol 176:1–8

Nadjafi M, Gholami P (2021) Reliability analysis of notched plates under anisotropic damage based on uniaxial loading using continuum damage mechanics approach. International J of Engineering 34:253–262

O’higgins MR, Padhi G, McCarthy M (2005) A study of damage initiation and growth in composite bolted joints. In: National symposium of the Irish research council for science, engineering and technology, p 287

O’higgins R, McCarthy C, McCarthy M (2011) Identification of damage and plasticity parameters for continuum damage mechanics modelling of carbon and glass fibre-reinforced composite materials. Strain 47:105–115

Okabe T, Onodera S, Kumagai Y, Nagumo Y (2018) Continuum damage mechanics modeling of composite laminates including transverse cracks. Int J Damage Mech 27:877–895

Onodera S, Okabe T (2020) Analytical model for determining effective stiffness and mechanical behavior of polymer matrix composite laminates using continuum damage mechanics. Int J Damage Mech 29:1512–1542

Phillips EA, Herakovich CT, Graham LL (2001) Damage development in composites with large stress gradients. Compos Sci Technol 61:2169–2182

Sepehri A, Selahi E (2019) Damage evaluation of protected and non-protected composite sandwich panels with insulation subjected to fire and impact loads. Iran J Sci Technol Trans Mech Eng 1–13

Shi D, Xiao X (2018) An enhanced continuum damage mechanics model for crash simulation of composites. Compos Struct 185:774–785

Sleight DW (1999) Progressive failure analysis methodology for laminated composite structures.

Standard A (2001) D3518/D3518M–94 (2001). Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ± 45° Laminate annual book of ASTM standards 15

Zhang S, Zhang C, Chen X (2015) Effect of statistical correlation between ply mechanical properties on reliability of fibre reinforced plastic composite structures. J Compos Mater 49:2935–2945

Zhang S, Zhang L, Wang Y, Tao J, Chen X (2016) Effect of ply level thickness uncertainty on reliability of laminated composite panels. J Reinf Plast Compos 35:1387–1400

Zhou X-Y, Gosling P, Ullah Z, Kaczmarczyk L, Pearce C (2017) Stochastic multi-scale finite element based reliability analysis for laminated composite structures. Appl Math Model 45:457–473

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

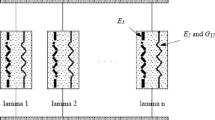

In this study, the material model described in the previous sections has been implemented using the subroutine code in finite element analysis ABAQUS software. In this process, the main problem is how to obtain the Jacobian matrix,\(J = \partial \Delta {\sigma /}\partial \Delta {\upvarepsilon }\), where \(\Delta {\upsigma }\) and \(\Delta {\upvarepsilon }\) are the stress and strain increment tensors, respectively. Generally, for this purpose, the calculation of the strain rates in terms of the stress rates is needed. Also, according to Eq. (7), this needs that the damage rates D2 and D12 should be obtained. As can be seen from Eq. (17), the values of the mentioned parameter are nonlinear functions of the conjugate forces Y, which Jacobian matrix J must be obtained based on.

Therefore, in terms of the engineering elastic constants the inverse strain–stress relations in this case become as follows (O’higgins et al. 2005):

Inverting Eq. (A1):

or in incremental form:

Therefore, the Jacobian matrix is:

where Aij, i, j = 1, 2, 3 is the material coefficient which will be calculated by substituting damage parameters [Eq. (17)] and their conjugate forces [Eq. (8)] in Eq. (7). These are given by (O’higgins et al. 2005):

Rights and permissions

About this article

Cite this article

Nadjafi, M., Gholami, P. Reliability Study of Notched Composite Laminates Under Uniaxial Loading Based on Continuum Damage Mechanics Approach. Iran J Sci Technol Trans Mech Eng 46, 911–925 (2022). https://doi.org/10.1007/s40997-021-00458-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-021-00458-w